Working from our clients data, we can develop the appropriate 3D models, tooling, fixtures, and jigs. This can be outputted to our various in-house machining disciplines including 5-axis or 3+2 CNC machines, manual mills and lathes. Occasionally we will outsource work packages to specialist service providers such as gun drilling or specialised finishes.

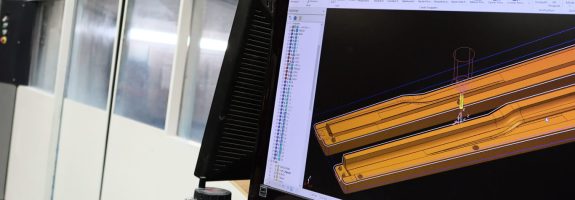

We utilise the latest CNC machine programming platforms such as Tebbis and Delcam Powermill. We are able to CNC machine in multiple types of material from steel/aluminium to polyurethane/epoxy composites along with most plastics like ABS & Nylon.

Full in-house CAD modelling and surface generation capability, using the latest release of Siemens NX and Dassault’s Catia V5. We can accept most common data translation files such as step and iges along with native NX and Catia formats. We can develop from concept part sketches or scanned data into 3D models, then to prototype through to tooling, fixtures, and jigs.

This system allows us to digitally acquire just about any physical item, large or small. The scanners are entirely portable so can be taken to the subject if necessary.

Capturing 1.3million points per scan, the data produced is highly suited to engineering applications such as reverse engineering as well as less technical uses such as animation, cultural heritage archiving, 3D medical libraries and visualisation work.

The resulting data is accurate to within 0,2mm. The scanners use optical structured light techniques, which are usually superior to laser scanners for edge detail and there is no size limit for the subject.