With 75 years of experience, we know that delivering the highest quality products & tooling at the lowest possible prices is just two of the reasons why our customers keep coming back

Established in 2006, APH3G is committed to delivering high-quality engineering solutions through advanced technology and precision tooling. With decades of industry expertise, we prioritise customer satisfaction, reliability, and innovation.

Our investment in people, partnerships, and ISO 9001:2015 accreditation ensures exceptional quality at competitive prices. Working closely with our customers, we provide expert guidance on tooling design, adapting to evolving requirements from concept to completion.

Concept, Design & Manufacturing in Vacuum Forming, GRP Moulding, RIM/PU Moulding, CNC Machining, Pattern Making, Tooling & CMM Inspection to our customers specification

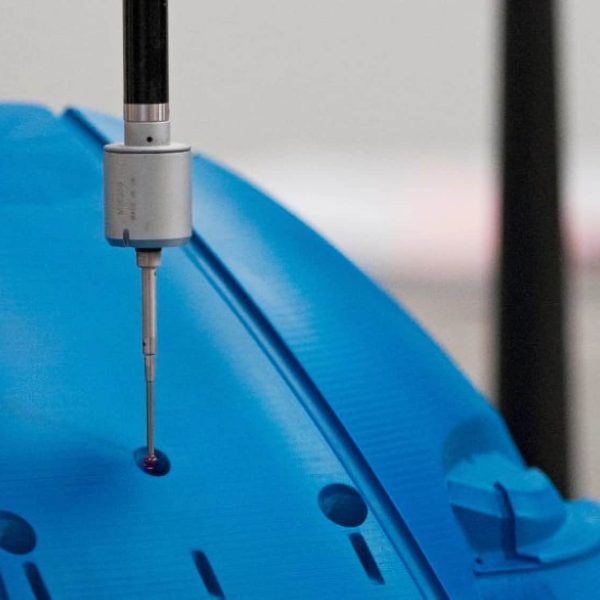

APH3G’s commitment to investing in new technology provides us with the latest CNC machines and CMM Inspection facilities. We can accommodate the machining of all materials (metallic & non metallic) up to 3,6 x 1,8 x 1,2 metres in size. Our inhouse manufacturing facility utilises nine CNC machines along with 5 axis capabilities available. In addition APH3G has it’s own in house inspection capability utilising a Stiefelmayer CMM with a bed size of 3,0 x 2,0 metres. Fully detailed inspection reports can be supplied to validate all functionality requirements requested by our clients.

APH3G offer prototype one offs and short runs up to production quantities of many 1000’s. We work with all vacuum formable materials ranging from HIPS to Fire Retardant Polycarbonate and thicknesses ranging from 0,25mm up to 10mm. In addition many of our customers in the aerospace, defence, railway and automotive industries require specialist materials, as dictated by the application of the end product.

APH3G undertake all aspects of Fibreglass producing our own patterns and plugs in house, from hand lay up of bespoke one off prototype through to low volume quantities of mouldings. Our patterns are made in a variety of materials that include MDF, Melamine, Ureol tooling board and Epoxy tooling board. The patterns are made either in our CNC machine shop or using traditional hand making methods by our own time served skilled team.

APH3G have been using this low pressure RIM system to produce a variety of PU components over many years. Our customer base include medical equipment and automotive interior trim panels and full body kits exterior panels. The cost advantages over injection tooling allow us to offer production of parts for prototype and relatively low numbered production runs.

Working from our clients data, we can develop the appropriate 3D models, tooling, fixtures, and jigs. This can be outputted to our various in-house machining disciplines including 5-axis or 3+2 CNC machines, manual mills and lathes. Occasionally we will outsource work packages to specialist service providers such as gun drilling or specialised finishes.

We utilise the latest CNC machine programming platforms such as Tebbis and Delcam Powermill. We are able to CNC machine in multiple types of material from steel/aluminium to polyurethane/epoxy composites along with most plastics like ABS & Nylon.

APH3G produce prototypes and models for a variety of applications from using traditional hand methods used by our skilled craftsmen, through to CNC machining from our CAD Masters. We also utilise the latest rapid prototyping techniques, these include SLS & SLA to build some or all of a model or prototype.

With our 3D CAD modelling system we can design a virtual jig or fixture to suit a client’s product. The design philosophy can be approved prior to manufacture ensuring the delivered product meets the client’s expectations. The fixtures are machined in house and the final assembly is checked via CMM to ensure functionality.

How best to reduce the assembly or manufacturing time of a product, is crucial to improving its quality and profitability. The correct design of special purpose jigs and fixtures is an integral part of the development cycle.

A CMM (Coordinate Measuring Machine) is a device which is used for measuring the physical and geometrical characteristics of an object. By probing discrete points on the components surface critical path dimensions and geometric features can be checked and reported on to ensure functionality is maintained and that process controls during manufacture are rigidly adhered to. Full reports can be provided to our end users to validate the quality process maintained within APH3G.

APH3G have been providing a CMM service for many years, it is an essential part of our capabilities.

Craftsmanship does not exclusively mean Automotive, in fact everything undertaken by APH3G has this element intuitively given by our time served Artisans. We believe that a passion for what we do, is perhaps the reason why our customers keep coming back to get a product, at the right price, the best quality, the quickest lead time, but with no compromise in the crafted end result.

In conjunction with our experienced painters we can now offer painting of your parts as required. We can paint all materials along with most composite and plastic materials (utilising appropriate primers and pre-treatments) and can cater for bespoke colour matched parts if required, along with the full spectrum of RAL and BS381C shades.

With 75 years experience, we know that delivering the highest quality products & tooling at the lowest possible prices is just two of the reasons why our customers keep coming back!

Over many years we have gained recognition as an OEM supplier, demonstrating that our diversity has many advantages, all under one roof we offer the ability to combine all our services eg. Vacuum Forming, Fibreglass Moulding, Rim/PU Moulding, CAD/CAM, Tooling & Craftmanship, so that quality fit and function is right first time, maintaining our reputation as the company who can support your vehicle projects.

We have several major vehicle OEMs who can rely on us to make sure that their end project is to the highest standard, to give you an idea of what we have been able to support:

Defence companies chose APH3G some time ago to produce a multitude of different vacuum formed ordnance protectors. To this day some of the same items are still produced, and now some of the detailed assemblies are used as covers for FLIR equipment.

To name a few projects which we have been able to support in the past: